I had the absolute pleasure of first touring the Kokomo Opalescent Glass Co. while on a trip with the artist, Dianna Kitzinger, who has created our stained glass piece for the back wall of the Vardo., and again just recently with Blue to custom order the replacement glass for the mollicroft.

The tour provided such a rich history. I’ve included an except from their site, below, and the link if you are interested in exploring further. Here’s just a teaser… did you know they are one of only four stained glass facilities in the U.S. and are the only one that still hand mixes their glass. They have 33,000 colors and an average gas bill of $65,000/month! They also continue to be the world’s leading producer of Tiffany glass. Through the tour and exposure to the site’s extravagant history we were left further appreciative of the beauty that rides on Isadora.

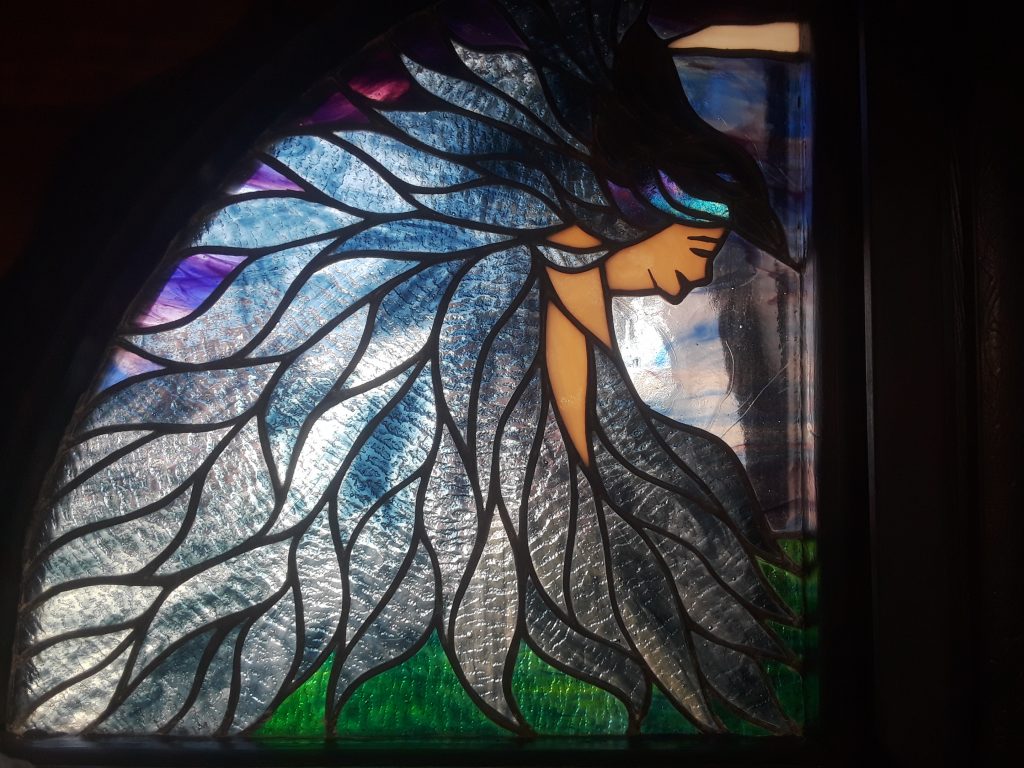

Our own artwork was designed in conjunction with Dianna and is a play off of our Blue Raven Sea Witch insignia. It is conceptually stunning! It all began with a flaming orange sheet of glass that she had held onto for years. It was such a brazen color she confessed she had no idea that it would ever find a fit. And of course I fell in love with the first glimpse! From there it was a blitz of texture and color, shape and artistry. Not to be overshadowed, the panels of garnet ruby red in the mollicroft splashes across the inside when the sun just whispers across it, leaving its own wash of frenzied color.

CURIOSITIES

Louis Comfort Tiffany – February 18, 1848 to January 17, 1933

Tiffany was odd in that he liked imperfections in the glass, which up to this point had been completely transparent in appearance; what we know today as cathedral glass. When Tiffany was unable to convince glass makers to leave impurities in their glass he began making his own glass. Tiffany used opalescent glass in a variety of colors and textures to create a unique style of stained glass. This is in contrast to the method of painting in enamels or glass paint on colorless glass that had been the dominate method of creating stained glass for hundreds of years in Europe. The use of colored glass itself to create stained glass pictures was motivated in part by the ideology of the Arts and Crafts movement lead by William Morris from England.

The first Tiffany commercially produced lamps date from around 1895. Tiffany Studios produced mainly glass windows and lamps with some additional interior decorations. At it’s peak Tiffany Studios employed more than 300 artists. In 1900, Mr. Tiffany won a gold medal at the Exposition Universelle in Paris with his stained glass windows “The Four Seasons” and continued with receive awards at international fairs through out America and around the world.

Kokomo Opalescent Glass, then known as The Opalescent Glass Works, specialized in this incredible new American style of glass – opalescent. Their long history of award winning glass began with the 1889 Paris Exposition Universelle where they received their own gold medal. Even as Tiffany’s own glass factory in Corona, NY was open he purchased glass form Kokomo Opalescent Glass. Many stained glass innovations are attributed to Mr. Tiffany and can still be found in Kokomo Opalescent Glass today such as their use of strong color, a huge variety of textures that include ripple glass, mottled glass (glass with areas of opaque and translucent spots of color), and marbleized (two or more opaque colors swirled together). Tiffany also used a considerable amount of jewels in his productions and Kokomo Opalescent Glass continues to produce old favorites and develop new pieces.

Mr. Tiffany’s furnaces ceased operations in the early 1930’s and he passed away in 1933. The plethora of work from Tiffany Studio’s that still survives today means that restoration work on many pieces are always ongoing. Kokomo Opalescent Glass continues to be the main source of glass for much of this work. They still produce nearly all of the same colors that Mr. Tiffany utilized in his work and have developed new colors and textures that resemble glass produced in his furnaces during that time period.